In an era where efficiency and precision define manufacturing competitiveness, CNC machine automation has emerged as a cornerstone for modern industry. By integrating advanced software and hardware, CNC machining solutions enable businesses to streamline workflows, reduce errors, and scale operations seamlessly. Leichman, a HOSTON sub-brand specializing in high-end CNC equipment, exemplifies how automation can elevate productivity across diverse sectors.

Enhanced Precision and Consistency

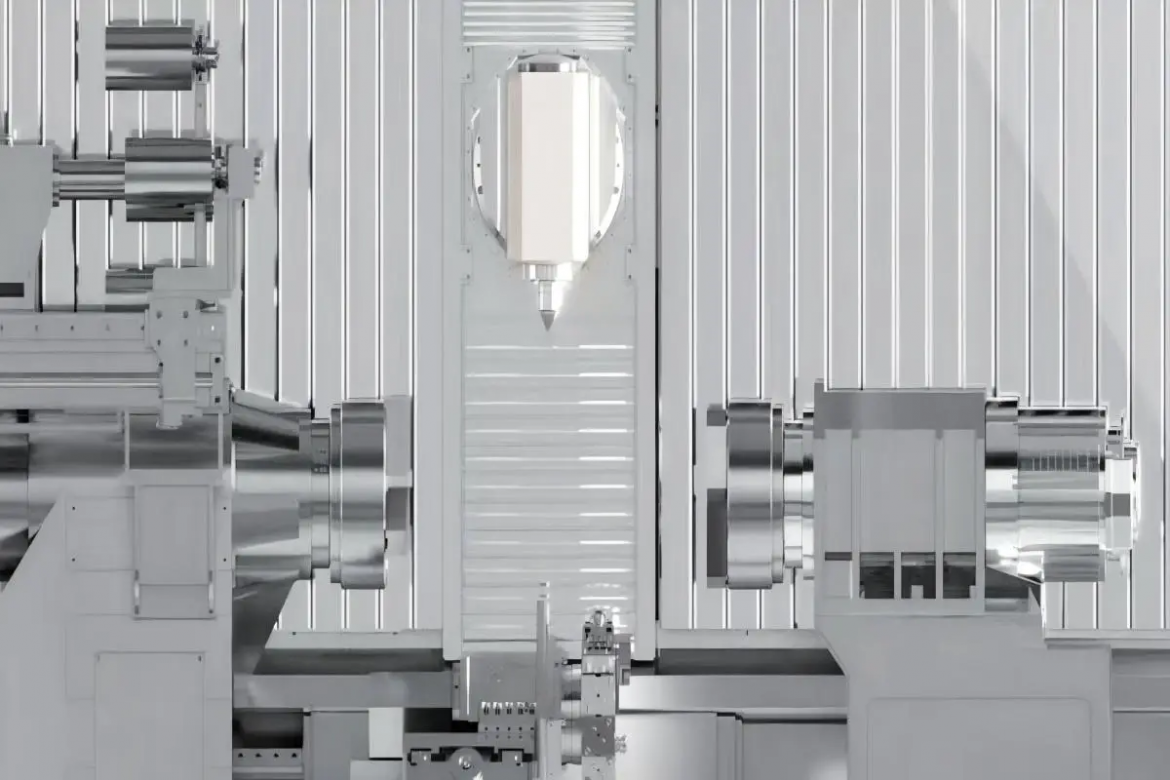

Manual machining is prone to human error, especially in repetitive tasks. CNC machine automation eliminates variability by executing pre-programmed instructions with micron-level accuracy. Leichman’s CNC solutions, powered by Syntec controllers and Japanese THK guide rails, ensure stable tool movement and minimal thermal deformation. This precision is critical for industries like aerospace or medical devices, where even slight deviations can compromise safety or functionality.

Cost Efficiency Through Reduced Labor and Waste

Automated CNC systems operate continuously, reducing reliance on skilled operators for basic tasks. Leichman’s machines, designed for 24/7 production, cut labor costs while minimizing material waste through optimized cutting paths. For example, their compact vertical lathes—ideal for small-batch manufacturing—feature automatic tool changers that reduce setup time by up to 50%. This efficiency makes CNC machining solutions a cost-effective choice for SMEs aiming to upgrade from manual processes.

Scalability and Flexibility for Evolving Demands

Leichman’s CNC machine automation supports customizable workflows, allowing businesses to adapt to changing market needs. Their low-order quantity policy (single-unit orders accepted) enables clients to test automation on a small scale before scaling up. Additionally, modular designs—such as adjustable spindle speeds or customizable control systems—ensure compatibility with diverse materials and part geometries, from automotive components to consumer electronics.

Conclusion

CNC machine automation redefines manufacturing by merging precision, efficiency, and adaptability. Leichman’ s CNC machining solutions demonstrate how automation can empower businesses to meet stringent quality standards while optimizing costs. With global expertise and tailored support, their systems provide a reliable pathway for industries seeking to future-proof their operations. For companies prioritizing scalability and reliability, investing in automated CNC technology is no longer an option—it’s a strategic imperative.