Scaling industrial automation components from a digital design to a physical reality is a high-stakes endeavor. For engineers and procurement managers in the US, finding a partner capable of handling this transition without compromising quality is critical. The journey from a prototype to millions of units involves navigating material behaviors, tolerance stacks, and supply chain logistics. Leveraging a proficient injection mold China service allows companies to bridge the gap between low-volume pilot runs and full-scale mass production, ensuring that medical devices and automotive parts meet rigorous standards.

Mitigating Capital Risk Through Strategic Bridge Tooling

Before investing in expensive hardened steel molds for mass production, manufacturers must validate their designs under real-world conditions. Bridge tooling, often utilizing aluminum or pre-hardened steel (P20), offers a strategic middle ground. It enables the production of 500 to 10,000 functional parts for market testing and assembly line verification without the substantial upfront costs and long lead times associated with production tooling.

Leveraging Soft Tooling for Functional Validation

Soft tooling is instrumental for de-risking the product development cycle. By using aluminum molds, custom injection molding manufacturers can deliver functional parts in as little as 10 to 15 days, compared to the 8 to 12 weeks often required for Class 101 steel molds. This speed allows R&D teams to physically test snap-fits, enclosures, and moving assemblies using production-grade resins rather than 3D-printed surrogates. Data from industrial case studies suggest that identifying design flaws at this stage reduces total project costs by approximately 30-50%, as modifying an aluminum tool is significantly faster and cheaper than reworking hardened steel.

Accelerating Market Entry with Agile Fabrication

Speed is a competitive advantage in sectors like consumer electronics and medical devices. Rapid tooling strategies utilize high-speed CNC machining and EDM (Electrical Discharge Machining) to create mold cavities quickly. This agility supports an iterative design process where feedback from pilot runs can be immediately incorporated into the final mold design. For instance, a medical device startup can secure regulatory approvals using pilot parts produced via bridge tooling while the high-volume production molds are simultaneously being manufactured. This parallel processing approach can shave months off the time-to-market, allowing brands to capture market share earlier.

Ensuring Process Stability During Mass Production Scale-Up

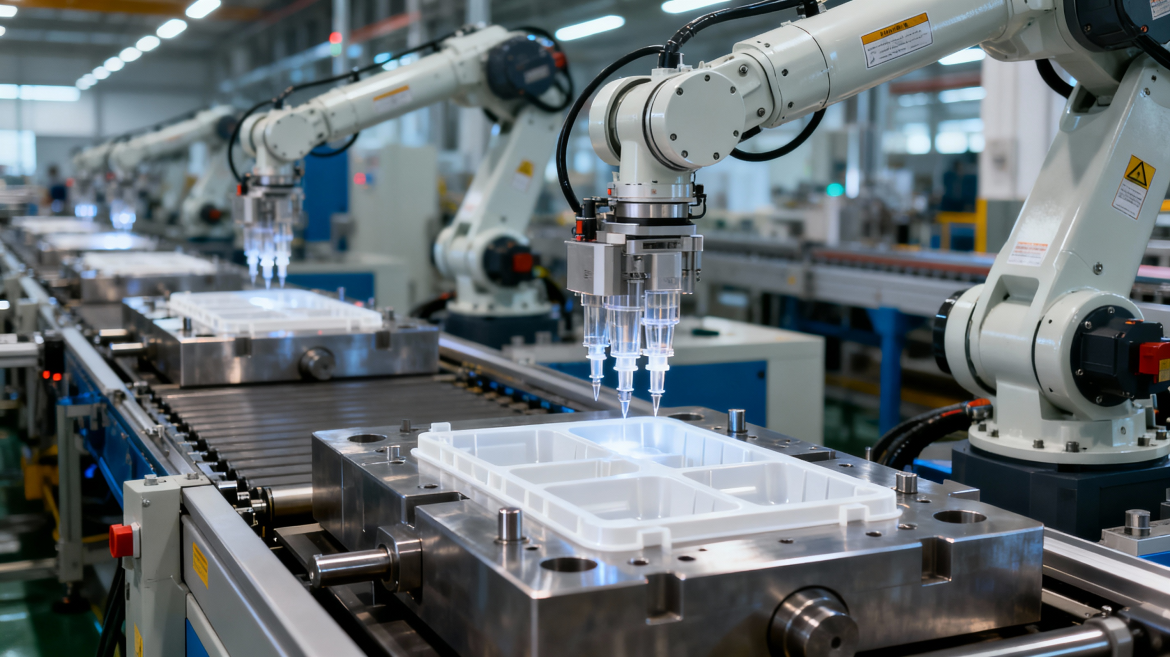

Transitioning from pilot runs to mass production requires a shift in focus from speed to absolute consistency. This phase demands the implementation of scientific molding principles to ensure that the millionth part is identical to the first. A capable injection mold service China provider will utilize decoupled molding techniques to separate the filling, packing, and holding stages, thereby minimizing part-to-part variation.

Implementing Scientific Molding for Repeatability

Scientific molding transforms injection molding from an art into a data-driven science. By monitoring key variables such as melt temperature, injection pressure, and cooling rates in real-time, manufacturers can establish a robust process window. For critical automation components requiring tight tolerances , achieving a Cpk (Process Capability Index) of 1.33 or higher is mandatory. Advanced sensors inside the mold cavity provide continuous feedback, allowing the machine to automatically reject any parts that deviate from the set parameters. This level of control is essential for preventing defects such as flash, short shots, or dimensional instability in high-volume runs.

Managing the Switch from Pilot to Mass Production

Determining the optimal switch point from soft to hard tooling is a calculated decision based on volume forecasts and tool life. While a soft tool may degrade after 50,000 shots, a Class 101 hardened steel mold is engineered to withstand over one million cycles. The transition involves rigorous validation protocols, including First Article Inspection (FAI) and Process Failure Mode and Effects Analysis (PFMEA). Experienced China injection molds suppliers manage this changeover by standardizing mold bases and utilizing interchangeable inserts, ensuring that the scale-up does not disrupt the supply chain.

Livepoint Tooling: Comprehensive One-Stop Manufacturing Capabilities

Livepoint Tooling distinguishes itself as a premier partner for global enterprises, offering an integrated solution that spans the entire product lifecycle. With over 23 years of experience in the industry, Livepoint provides a seamless “One-Stop” service that eliminates the complexity of managing multiple vendors.

End-to-End Production: From initial CNC machining and 3D printing for rapid prototypes to the fabrication of high-precision multi-cavity molds for mass production.

Certified Quality: The facility operates under strict ISO 9001:2015 and IATF 16949 quality management systems, ensuring compliance for automotive and industrial sectors.

Advanced Capabilities: Expertise includes 2K (two-shot) molding, insert molding, and overmolding, catering to complex functional requirements in medical and new energy applications.

Global Reach: Serving clients such as Tesla and Volkswagen, Livepoint demonstrates the capacity to handle mission-critical projects with reliable delivery and engineering support.

By consolidating design, tooling, and molding under one roof, Livepoint Tooling reduces communication risks and accelerates project timelines, providing a secure pathway for industrial scale-up.