Extreme climates place electrical infrastructure under continuous mechanical, thermal, and environmental pressure. In these regions, incorporating both power utility solution and electrical power solutions becomes essential for stable grid operation. When grids face heatwaves, severe dust, coastal salt fog, or sudden temperature swings, materials and hardware must withstand accelerated aging and higher mechanical loads. In this context, they apply climate-resilient engineering to maintain consistent performance. As part of broader infrastructure projects, SH POWER provides components designed for long-term operation under fluctuating environmental stress. Their experience shows how these solutions help utilities reduce failure rates and maintain predictable system behavior.

Climate-Adapted Hardware as a Foundation for Reliability

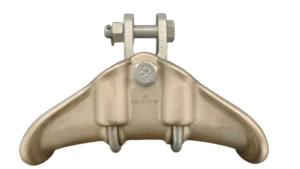

The influence of electrical power solutions is especially visible in networks exposed to both sandstorms and high humidity. Utilities gain stability when they select hardware engineered for mechanical endurance and corrosion resistance. A practical example comes from the Algeria National Power Grid Upgrade Project, where they supplied a high-strength corrosion-resistant design. Utilizing high-strength aluminum alloy with a hot-dip galvanizing process, the hardware adapts to high temperatures, dust, and coastal high-salt fog, supporting maintenance-free operation for up to 30 years. Meeting IEC 61284 requirements for 400kV/220kV lines, it demonstrates how a well-designed power utility solution improves long-term system resilience without relying on excessive maintenance.

Efficiency and Adaptability as Key Performance Drivers

In extreme climates, every component’s weight, electrical characteristics, and installation efficiency affect overall grid reliability. Structural optimization that reduces hardware weight by 15% helps limit tower load while improving transmission efficiency. These considerations explain why utilities increasingly adopt power utility solution frameworks that focus on both durability and system economy. Through low-corona design and lightweight materials, SH POWER integrates electrical power solutions that also minimize energy loss during high-voltage transmission. Their components are precisely matched with AAAC 570 mm² conductors and support temperatures from –40°C to 80°C. The modular structure shortens construction periods, offering practical advantages during rapid deployment in harsh conditions.

Conclusion: How Electrical Solutions Strengthen Grids in Extreme Climates

Extreme environments amplify mechanical stress, accelerate corrosion, and introduce operational uncertainty. By integrating durable materials, efficient structures, and adaptable configurations, electrical power solutions directly influence grid stability. Climate-resilient hardware, such as that used in Algeria, illustrates how engineering-based power utility solution approaches ensure dependable operation. With experience in demanding regions, SH POWER demonstrates how carefully engineered components help utilities build grids that continue performing reliably despite environmental challenges.