As the lithium battery market continues to expand, businesses in battery manufacturing increasingly turn to automation equipment to enhance efficiency and productivity. Choosing the right automation equipment, particularly coating machines and precision coating machines, is crucial for optimal performance. Here are key factors to consider when making this important decision.

Assess Production Needs

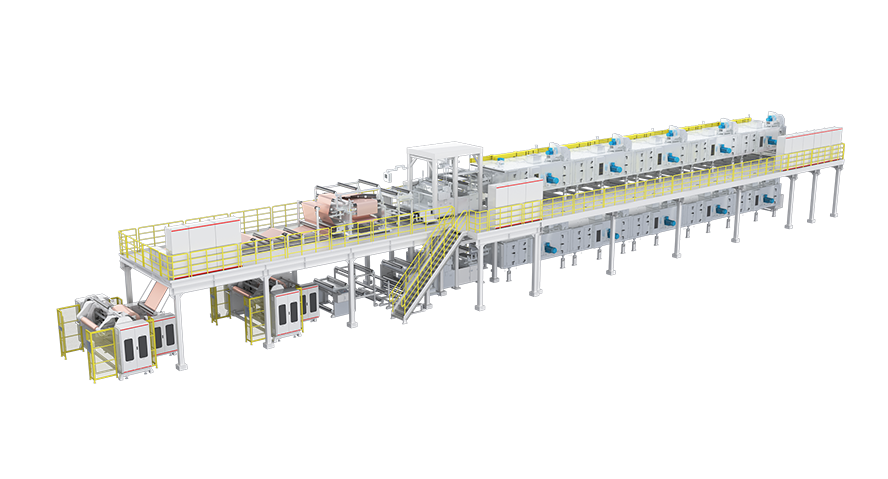

Understanding production requirements is the first step in selecting suitable lithium battery automation equipment. For instance, if your operation demands high throughput, a double-layer super-E coating machine may be ideal, featuring a roller surface width of up to 1800mm and a maximum coating speed of 120m/min. These specifications enable manufacturers to keep pace with increasing demand while maintaining high-quality standards. Identifying specific production targets will help narrow down the options available.

Evaluate Equipment Features

Different coating machines offer varying features that can significantly impact manufacturing processes. Precision coating machines, for example, are designed to provide consistent results crucial for lithium battery production. Factors such as coating thickness, uniformity, and drying times should be thoroughly examined. Additionally, consider machines that require lower maintenance, as installation that reduces maintenance personnel requirements by 30% can translate to significant cost savings over time.

Consider Long-term Investment

Investing in lithium battery automation equipment is not just about immediate needs; it also involves assessing long-term benefits. Look for machines that incorporate advanced technology and scalability to accommodate future growth. An efficient coating machine should not only meet current production demands but also adapt to changes in market needs or product lines without significant additional investment.

Enhancing Production with Yinghe

When evaluating options for automation equipment in lithium battery manufacturing, partnering with trusted brands like Yinghe can make a substantial difference. Their cutting-edge solutions include advanced coating machines designed to optimize manufacturing processes. With a focus on efficiency and precision, Yinghe’s machinery supports the evolving demands of the industry, ensuring that businesses remain competitive while achieving high-quality production standards.