Have you ever wondered how industries create metal parts with intricate shapes and flawless precision — parts that look identical even when produced in thousands? Imagine a production line where molten metal is shaped into durable components within seconds, each piece emerging ready for assembly. This is the power of die casting, a process that combines engineering precision with production efficiency.

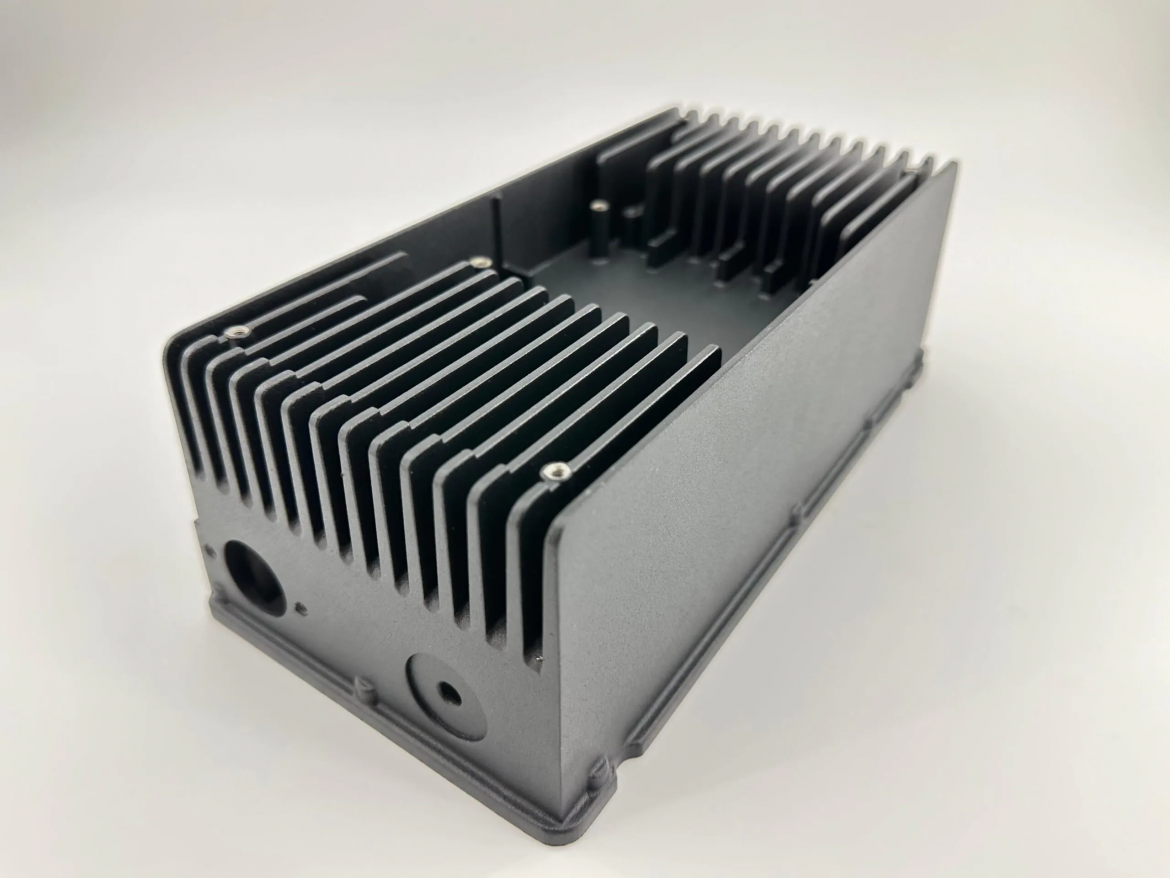

Die casting is a manufacturing method where molten metal is injected into precisely designed molds, called dies, under high pressure. This process allows for the creation of metal parts with complex shapes, consistent dimensions, and smooth surfaces. Many industries rely on this approach for high-volume production because it reduces the cost per unit while maintaining reliable quality.

Advantages of Working with a Die Casting Manufacturer

Partnering with an experienced die casting manufacturer ensures that each component meets strict specifications. Manufacturers like Dingmetal specialize in delivering high-quality parts that require minimal post-processing, thanks to advanced machinery and expertise in metal flow control. Whether producing hundreds or thousands of units, working with a capable partner ensures that components maintain tight tolerances and intricate geometries, which are difficult to achieve with alternative manufacturing methods.

Custom Die Cast Solutions for Complex Components

For businesses requiring specific designs, custom die cast services provide flexibility in both shape and material selection. Dingmetal offers OEM and ODM solutions, tailoring each die cast part to meet your functional and aesthetic requirements. By focusing on precision and repeatability, custom die casting supports faster production cycles and reduces the need for extensive machining or finishing.

Choosing the Right Partner

Selecting a reliable die casting manufacturer is crucial for projects where consistency, durability, and cost efficiency are priorities. Dingmetal combines technical expertise with advanced equipment to deliver die cast components that meet diverse industry standards. Their approach ensures that each project benefits from optimized tooling, efficient production, and reliable performance.

The Value of Die Casting

Understanding how die casting works helps businesses recognize its value in producing high-quality metal parts efficiently. With experienced partners like Dingmetal, companies can leverage both standard and custom die cast solutions to achieve complex designs with precision, speed, and cost-effectiveness. Collaborating with a professional die casting manufacturer can streamline production, reduce post-processing needs, and support successful product development.