The conversion of electrical energy into mechanical power varies significantly between motor architectures. When comparing a brushless motor to a traditional brushed DC electric motor, efficiency emerges as a defining differentiator. The fundamental design of a brushless motor eliminates a primary source of energy loss, establishing its performance advantage in demanding applications.

The Impact of Brush Friction and Electrical Loss

A brushed DC electric motor operates with physical carbon brushes pressed against a commutator. This constant contact creates mechanical friction, which converts useful energy into waste heat. Furthermore, electrical energy is lost as resistance across the sliding contact point. These combined losses can substantially reduce the overall efficiency of the brushed electric motor, especially at higher speeds.

Electronic Commutation in BLDC Systems

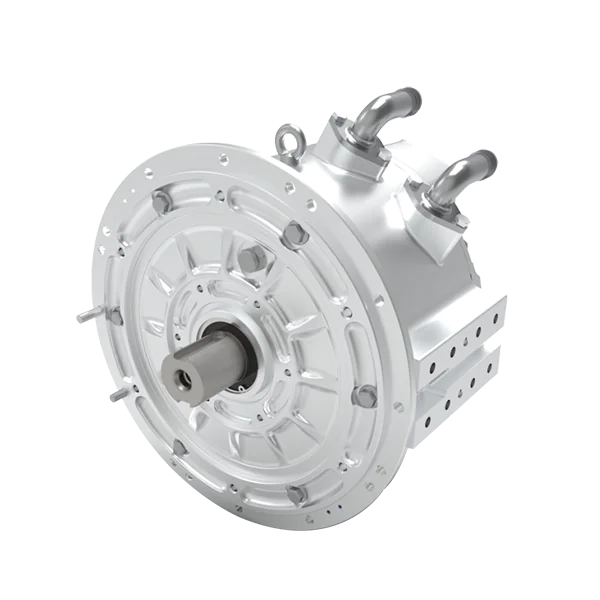

In a brushless motor, the commutation function is managed electronically by an external controller. This design removes the brushes and the associated friction and electrical resistance losses. The brushless motor relies on permanent magnets and precisely timed current delivery to the stator windings, resulting in a more direct transfer of energy and higher operational efficiency.

Thermal Performance and Long-Term Reliability

The reduced energy loss in a brushless motor directly correlates to lower operational temperatures. Excessive heat is a primary cause of insulation degradation and bearing wear in any electric motor. By generating less waste heat, the brushless motor not only conserves energy but also promotes greater long-term reliability and an extended service life, reducing total cost of ownership.

The efficiency gap between these technologies is therefore structural. The absence of mechanical commutation allows the brushless motor to operate with less wasted energy, lower heat generation, and superior performance consistency. For applications where energy consumption, thermal management, and durability are priorities, the technical merits of a brushless motor from a provider like Santroll present a compelling case over traditional brushed DC alternatives.